Why work with DECOREC?

You want to:

Obtain dimensional AND geometric tolerances with very high accuracy within +/- 5 μm.

Improve surface state of your part to Ra <0.2 AND ensure the proper function of your sub-assembly.

Build up a lasting relationship with a local partner AND be able to deliver internationally.

Work together with DECOREC

Its the promise to have a sole partner who can master in-house the process from A to Z.

Improve technologically

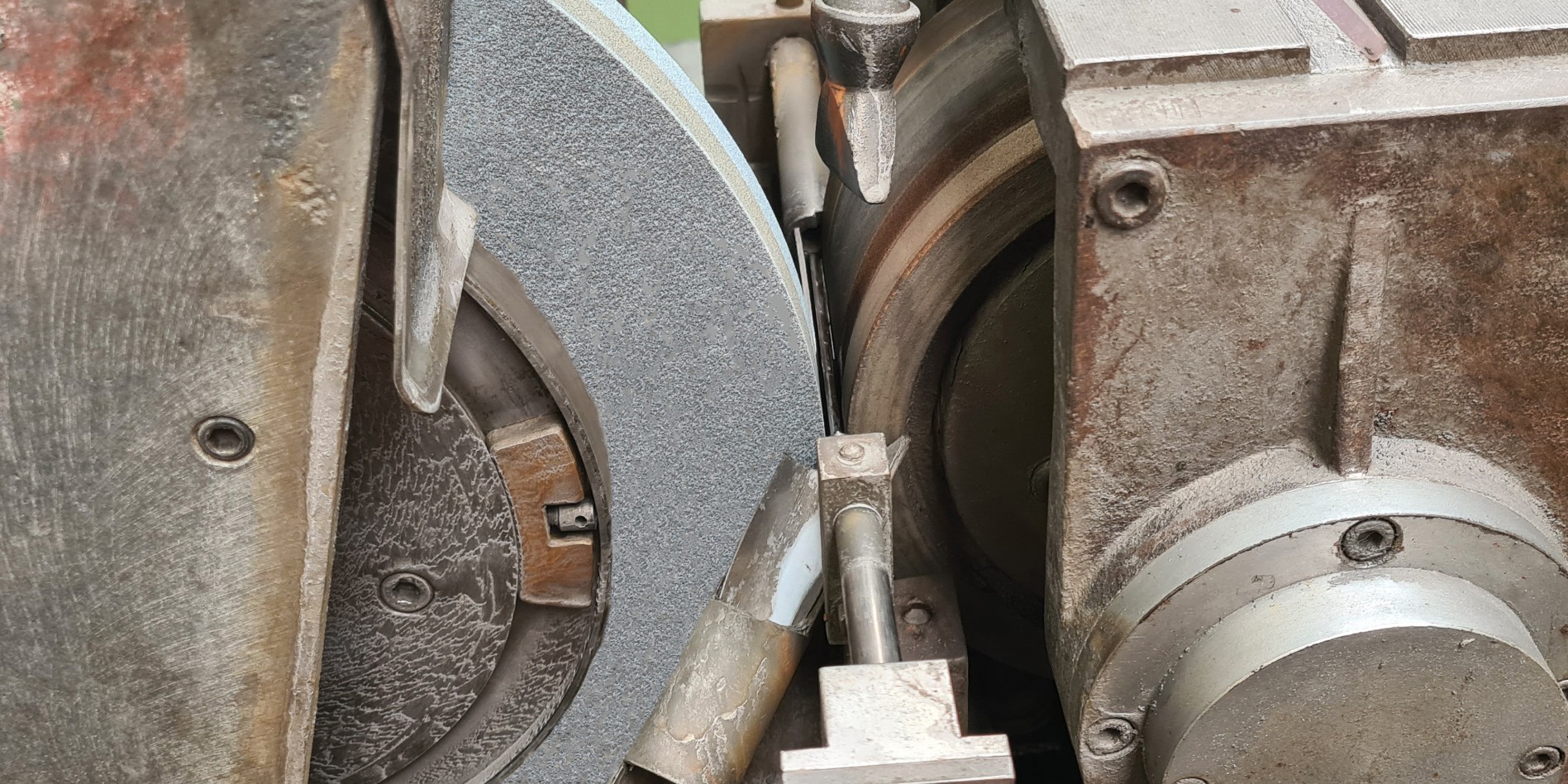

Having an overall vision of the whole process ensures a better workflow: testing, adjusting and feedback done together in the bar-turning and grinding workshops.

Reduce costs

One unique manufacturer so no hidden extras of sub-contracting nor logistics.

Optimise leadtimes

No external transport between bar-turning and grinding operations.

Co-operate with a partner able to improve and/or design dedicated machines

Parts handling is automised in-house thanks to a system developped by our own design office.

Some specifications

Some examples of parts that we grind for the automobile and medical sectors:

- Filters

- Throttles

- Ball joints

- Valve stems

- Pistons

Technical characteristics of machining

- Materials: Steels for bar-turning 1.0758, 1.0762, 1.3505, stainless steel 1.4404, 1.4104, brass CW603N, CW614N, lead-free brass, other variations possible

- Diameter: from 2 to 51 mm

- Tolerance +/- 5 μm with Cpk > 1.67

- Roughness Ra <0.2

- Series size: 2,000 to 400,000 parts